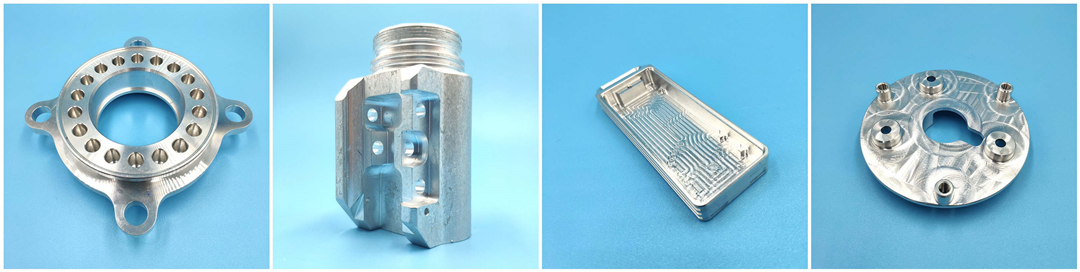

2019 wholesale price camera photographic equipment parts parts milling safety camera small parts thread rolling hard anodized aluminum, anodized aluminum camera parts aluminum camera casing, spare parts mobile phone camera Dslr camera spare parts, in addition, we get experienced, knowledgeable professionals Support, they have a wealth of expertise in their respective fields. These professionals work closely together to provide an effective product range for our customers.

2019 wholesale price camera photographic equipment parts parts milling safety camera small parts thread rolling hard anodized aluminum, anodized aluminum camera parts aluminum camera casing, spare parts mobile phone camera Dslr camera spare parts, in addition, we get experienced, knowledgeable professionals Support, they have a wealth of expertise in their respective fields. These professionals work closely together to provide an effective product range for our customers.| Finish Result | |

| As Machined | Sharp edge and burrs will be removed |

| Bead Blast | The part surface is left with a smooth, matte appearance |

| Anodized | Type II creates a corrosion-resistant finish. Parts can be anodized in different colors—clear,black, red, and gold are most common—and is usually associated with aluminum. |

| Type III is thicker and creates a wear-resistant layer in addition to the corrosion resistanceseen with Type II. | |

| Powder Coat | This is a process where powdered paint is sprayed onto a part which is then baked in an oven.This creates a strong, wear- and corrosion-resistant layer that is more durable than standardpainting methods. A wide variety of colors are available to create the desired aesthetic. |

| Customized | As Requirement |

| Others | |

| Tolerance | +/-0.005mm |

| Lead Time | 1-2 weeks for samples,3-4 weeks for mass production |

| Drawing Accepted | Solid Works,Pro/Engineer, AutoCAD(DXF,DWG), PDF,TI |

| Payment Terms | Trade Assurance, TT/ Paypal / West Union |

| cheap metal fabrication | cnc aluminium turning parts | cnc milling parts manufacturers |

| china machining | cnc automatic turning | cnc milling plastic |

| chinese machining companies | cnc machining processing turning small metal parts | cnc plastic |

.jpg)